Magnetic Proximity Sensor-Working Principle, Applications

The blog covers the basics of magnetic proximity sensors, its working, applications, and advantages and disadvantages.

Proximity sensing is the technique of detecting the presence or absence of an object using a critical distance. In this blog, we are talking about the working principle of Magnetic Proximity Sensor, also features and applications. Magnetic proximity sensors are non-contact proximity device which detects the magnetic objects (e.g. permanent magnets). They sense the presence of a magnetic object.

Basics of Magnetic proximity sensor

Magnetic proximity sensors use for non-contact position detection beyond the normal limits of inductive sensors. In conjunction with a separate “damping” magnet, magnetic sensors offer very long sensing ranges from a small package size and can detect magnets through walls of non-ferrous metal, stainless steel, aluminum, plastic or wood.

Depending on the orientation of the magnetic field the sensor damped from the front or from the side. In the food industry, the magnetic sensor uses in connection with a cleaning devices which pass through the inside of pipes.

Output of Magnetic proximity sensor

The magnetic field sensor output can be linear in which its output voltage linearly relates to the magnetic field strength impinging on the detector, or binary in which the output is in one state when the measured magnetic field strength is greater than a particular threshold, and in the other state when the measured magnetic field strength is less than the threshold. Binary proximity sensors use to replace simple position-determining mechanical switches because they have no moving parts to wear or jam, and are therefore more reliable than their mechanical counterparts.

MUST READ BLOGS ON PROXIMITY SENSOR

- How proximity sensor works?

- Different types of proximity sensor

- Working principle of Inductive Proximity Sensor

- Inductive proximity sensor

- Capacitive proximity sensor

- Photoelectric proximity sensor

Features of Magnetic proximity sensor

- Detection through plastic, wood, and any non-magnetisable metals

- Small housings with very long sensing ranges up to 70 mm

- Cylinder and rectangular designs satisfy space-dependent applications

- High mechanical stability in case of shock or vibration

- Flush or non-flush installation in non-magnetisable metals

Working Principle of Magnetic Proximity Sensor

There are several operating principles used including reed switches, GMR inductive, variable reluctance, magneto resistive or hall effect sensors.

-

Variable reluctance

proximity sensors comprise of a permanent magnet and a pick up coil. A VR sensor uses as a simple proximity sensor can determine the position of a mechanical link in a piece of industrial equipment.

A Crankshaft position sensor (in an automobile engine) uses to provide the angular position of the crankshaft to the Engine control unit. The Engine control unit can then calculate engine speed (angular velocity).

A pickup uses in an electric guitar or in other musical instrument detect vibrations of the metallic "strings".

-

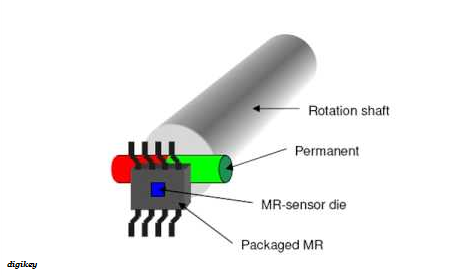

Magneto-resistive

proximity sensors measure the magneto-resistive effect or the impact of the resistivity of a ferromagnetic material in the presence of a magnetic field.

Magneto-resistance is the tendency of a material to change the value of its electrical resistance in an externally applied magnetic field.

-

Reed Switches

Reed switches are magnetically actuated switches. They typically manufacture with two ferromagnetic reeds (contact blades), which sealpowered in a glass capsule. In which consist of two low reluctance ferro-magnetic reeds enclosed in glass bulbs containing inert gas.

A magnetic field from an electromagnet or a permanent magnet will cause the reeds to attract each other to establish an electrical circuit. An example of a reed switch application is to detect the opening of a door, when used as a proximity switch for a security alarm.

-

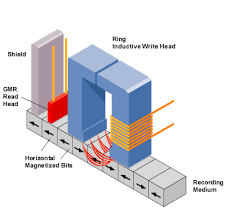

Giant Magneto-Resistive Effect

Magnetic sensors use GMR (Giant Magneto-Resistive Effect) technology.

The measuring cell consists of resistors with several extremely fine, ferromagnetic and non-magnetic layers.

Two of these GMR resistors use to form a conventional Wheatstone bridge circuit which produces a large signal proportional to the magnetic field when a magnetic field is present. A threshold value defines and an output signal switches via a comparator.

The main application of GMR is magnetic field sensors, which use to read data in hard disk drives, biosensors, microelectromechanical systems (MEMS) and other devices. GMR multi layer structures also use in magneto-resistive random-access memory (MRAM) as cells that store one bit of information.

-

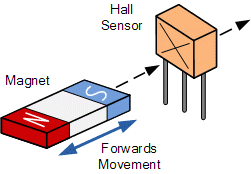

Hall effect sensor

Hall effect sensor is a device that uses to measure the magnitude of a magnetic field. Its output voltage is directly proportional to the magnetic field strength through it.

Hall effect sensors used for proximity sensing, positioning, speed detection, and current sensing applications. Frequently, a Hall sensor combines with threshold detection so that it acts as a switch.

Advantages of Magnetic proximity sensor

- Contacts are well protected against dust, oxidization and corrosion due to the hermetic glass bulb and inert gas; contacts are activated by means of a magnetic field rather than mechanical parts

- Special surface treatment of contacts assures long contact life

- Maintenance free

- Easy operation

- Reduced size

Applications of Magnetic proximity Sensor

Magnetic sensors are used in many industrial applications for contactless current sensing, linear and angular position, and rotation sensing. Crocus’ magnetic sensors are designed to provide superior performance in all of these applications.

-

Magnetic Sensors for PDU

The PDU (Power Distribution Unit) is a critical part of the data center infrastructure. PDU equipment uses to supply AC or DC electrical power to servers. Typically, the PDU provides power filtering and intelligent load balancing together with remote monitoring.

-

Robotics and Factory Automation

In factory automation, Both linear and angular position sensing are imperative to carry out complex motor movements with high precision, repeatability and accuracy. With the need for faster more efficient production lines, magnetic sensors are also used for linear and angular sensing, safety switches, and proximity detection.

-

White Goods

New regulatory requirements for energy and water conservation in appliances can accomplish through additional intelligent sensing. Crocus magnetic sensors provide the added intelligence for open/close door detection, fluid level, and contactless current sensing.

-

Used in Green Energy

When it comes to alternative energy such as with wind and solar, magnetic sensors provide contactless current sensing, angular position sensing and switches. For wind power, the angular position sensing allows for optimal wind power generation, while contactless current sensors provide solutions for power inverters and solar combiner boxes. Switches can also assist with safety applications in high voltage environments.

We at Robu.in hope that you found it interesting and that you will come back for more of our educational blogs.

Yet another excellent article from you, all useful in stuffing my head up with helpful knowledge.

I have also taken the time to share it on Facebook 🙂